When you are looking to waterproof an existing or new building you are likely to come across the term ”hydrostatic pressure”. It sounds very scientific and complex. Hydro definitely means “water”, but what’s with “static”?

The term is easily understood, but the concept is a bedeviling problem for builders and engineers.

Hydrostatic pressure is, in its simplest form. The pressure that water places against everything else around it.

It causes problems in building, for reasons explained below, yet is a necessary feature of our water systems and water pressure in our homes.

Hydrostatic pressure can be the enemy

In building, one of the first and biggest problems to solve is how to keep your foundation dry, and to keep water away.

One of the great problems is caused by hydrostatic pressure.

The concept can be as complex as this, as described at edinfomatics.com:

Hydrostatic pressure is the pressure that is exerted by a fluid at equilibrium at a given point within the fluid, due to the force of gravity. Hydrostatic pressure increases in proportion to depth measured from the surface because of the increasing weight of fluid exerting downward force from above.

However, the concept is as simple as this: the further underground your building meets with water, the more pressure that water is placing against your walls. This is mostly explained by gravity, but also by other forces.

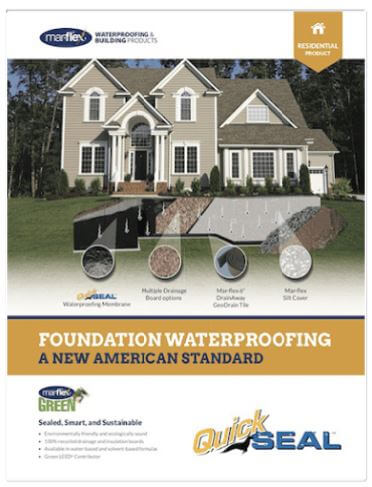

The best waterproofing plans for new construction and existing construction involve reducing hydrostatic pressure by directing water away from your foundation every way possible.

Hydrostatic pressure can be a friend

Hydrostatic pressure isn’t just for forcing water into your foundation, however.

Mankind learned a long time ago about the concept, and we have harnessed it to create … water pressure.

By utilizing tanks raised high above our communities and buildings, we have created a system that allows water to flow freely into our sinks, toilets, and showers. We simply pump the water up into the local water tower, and let hydrostatic pressure – also known as gravity – do the work from there.

You can see that hydrostatic pressure is an important concept to understand, whether it is working for you or against you.

Mar-Flex waterproofing offers a range of solutions designed to keep your foundation dry at whatever depth your plans require.