https://www.istockphoto.com/photos/cracked-foundation

If you suspect that your home may be having foundation issues, it might be time to ask a professional for help. Before that, here are some things to know about your home foundation.

Your home foundation can lead to several general issues throughout your house, including cracked walls, uneven door frames, windows pulling away from the wall, and uneven floors. You might notice that some of those problems can be located nowhere near the foundation itself – foundation problems affect all areas of your home. Do not take any sign lightly, despite how far away it is from the foundation itself.

If you notice any of these things you might have an issue with your home’s foundation, or at least have reason to inspect further. Some specific things to look out for are doors beginning to stick as you open and close them, cracks of any size in the floor, numerous nails coming out of drywall, and long splits in the brick around your house (if your house has brick). There are both interior and exterior signals; that is the start of a long list of warning signs. If you are worried about damage, give the inside and outside of your house equal attention to find the signs.

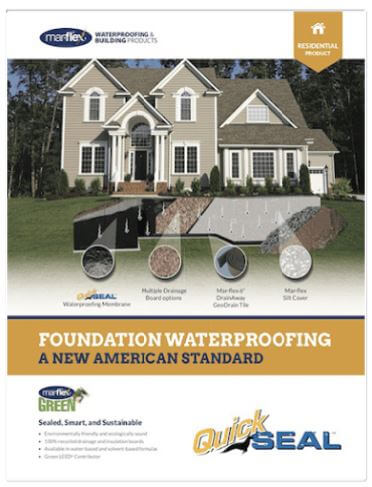

The signs of damage can also vary with each type of foundation. There are several common types: crawl space foundations, concrete slab foundations, wood foundations, basements, and stone foundations. Knowing the type your home has will also inform whether the signs of damage should be inspected further.

Regardless of what the problem is, you should not turn a foundation issue into a do it yourself (DIY) project. Without the proper care and attention, these problems can expand, leading to collapsed walls, increased water damage, and a significant decrease in property value for your home. Some local home inspectors will give you an estimate on repair costs at no charge; contacting them is the smartest and safest route to go with any foundational damage. Write down the signs and be as specific as possible with when you noticed them, how they have changed, and where they are located in your home.

At the end of the day, it is better to be safe than sorry when approaching damages to your home. Unless you are an expert, do not consider tackling this issue on your own. Risking the safety of yourself and your family/housemates is not worth saving money on an inspection.